|

|

|

|

THE FOUNDING OF A BUSINESS

On the strength of his experience in the agricultural tires sector, Michel Phely founds OTICO as a tire wholesaler and service provider. Its offices and headquarters are in Provins.

SWITCHES TO INDUSTRIAL MODE

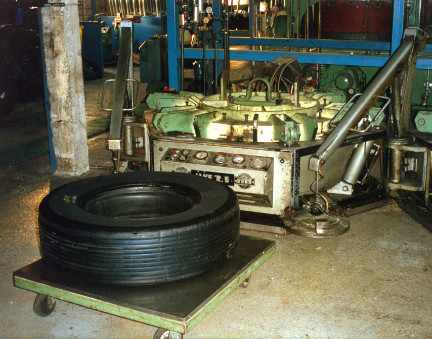

OTICO moves to its present site in Chalmaison and, as a pioneer in recycling, begins retreading heavy goods vehicle tires and then agricultural tires.

DIVERSIFIES INTO THE FLAX INDUSTRY

The company also diversifies by buying a production plant to make belts used in flax harvesting.

BEGINS RETREADING AIRCRAFT TIRES

The first partnerships with manufacturers of agricultural machinery, to optimise equipment in contact with soil for agricultural bins.

OLIVIER PHELY JOINS THE COMPANY

OTIFLEX BRAND FOUNDED

Olivier Phely takes over as technical director of OTICO and invents the production of semi-hollow tire for bins and seed drills, under the OTIFLEX brand, for RIBOULEAU- MONOSEM.

TERRAFLEX BRAND FOUNDED

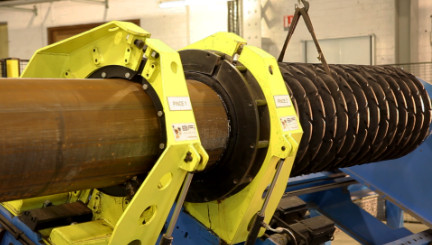

OTICO innovates by creating the first range of tire-mounted crawler tracks, under the TERRAFLEX brand for its customer PONCIN.

DESIGNS AND PRODUCES THE FIRST SEMI-HOLLOW ROLLER

DESIGNS AND PRODUCES THE FIRST POSITIVE-DRIVE CRAWLER TRACK SYSTEM.

Acquires its German rival FARMFLEX, a Continental Group brand, which will become OTICO's semi-hollow brand.

OLIVIER PHELY BECOMES PRESIDENT OF OTICO

and continues to grow the company by diversifying the FARMFLEX range of semi-hollow rollers and by modernising and increasing the capacity of the production plant.

OTICO WINS NEW MARKETS

in North America, Russia and Ukraine.

NEW EXTRUSION LINE OPENS

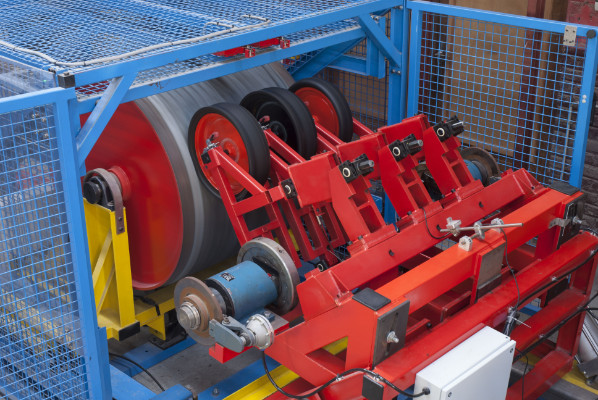

and a new facility with 50 presses and moulds. First test bench installed for wheels and rollers.

NEW WHEEL ASSEMBLY WORKSHOP CREATED

with a capacity of 10-15,000 wheels per week.

Robotisation

First robotised extrusion line is installed, specially for the production of semi-hollow FARMFLEX.

OTICO BRANCHES OUT INTO SOUTH AFRICA.

NEW SITE PURCHASED NEAR PROVINS,

dedicated to wheels / new & retreaded tires business: 20,000 m², of which 5,500 m² are a covered storeroom and workshop.

NEW ROLLER-ASSEMBLY WORKSHOP CREATED.

SECOND EXTRUSION LINE CREATED, EQUIPPED WITH A ROBOT.

NEW STOREROOM OPENS

for storing components and raw materials: 700m² floor area, 9m high.